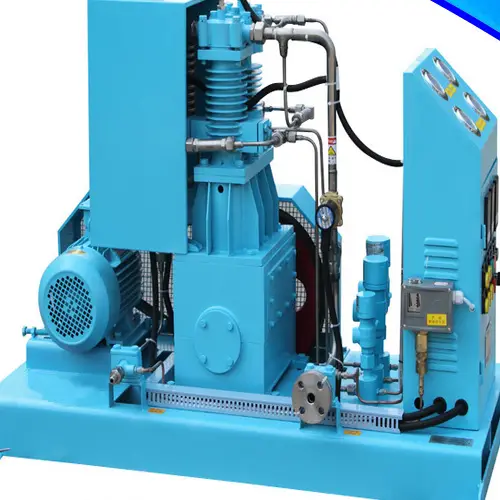

China Professional Oil-Free Special Gas Air Booster Compressor Pump: Small Air Compressor

The China Professional Oil-Free Special Gas Air Booster Compressor Pump is a top-of-the-line small air compressor designed specifically for the compression and recovery of SF6 gas. With its oil-free lubrication reciprocating type compressor and hermetic construction, this compressor offers numerous advantages such as reliable performance, simple operation, compact construction, and quick connection.

Product Description

The Oil-Free SF6 Gas Compressor is a semi-hermetic compressor that adopts a hermetic construction for its motor. This unique feature ensures that there is no pollution to the medium being compressed and no leakage. It operates on the principle of oil-free lubrication reciprocating type compressor and can be cooled by either wind or water. With a power consumption ranging from 1.5 to 45kw, an RPM range of 400 to 800rpm, and a capacity range of 1 to 200Nm3/h, this compressor is versatile and efficient.

Performance Characteristics

1. Working principle: Oil-free lubrication reciprocating type compressor

2. Cooling type: Wind or water cooling

3. Power consumption: 1.5-45kw

4. RPM range: 400-800rpm

5. Capacity range: 1-200Nm3/h

6. Inlet pressure: -0.1-20bar

7. Outlet pressure: 2-80bar

8. Compressed grade: 1-4

Our oil-free special gas compressor is designed for industries that require a pure air supply source and have higher environmental requirements. It is a fully oil-free lubricated, reciprocating piston type, single-acting air cooled compressor. The compressor can increase the lower pressure of special gases to satisfy industrial production requirements with minimal or no leakage, low noise, and reliable operation. It is the perfect solution for industries that need special gases of higher purity and higher pressure.

For more information, please do not hesitate to contact us.

Ever-Power Group: Your One-Stop Supplier for Industrial Products

Ever-Power Group is a leading supplier of various industrial products, providing a wide range of high-quality, reliable, and cost-effective solutions. Our product offerings include agricultural gearboxes, power output shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, roller chains, pulleys and pulleys, planetary gearboxes, timing pulleys, bushings, and more. We are committed to delivering products that meet the highest standards and exceed customer expectations.

At Ever-Power Group, we prioritize customer satisfaction by offering competitive prices, exceptional service, and the flexibility to customize products based on specific requirements. Whether you need custom drawings or samples, our experienced team is ready to assist you. Choose Ever-Power Group for your industrial product needs and experience the difference.

Frequently Asked Questions (FAQs)

1. What is the working principle of the Oil-Free SF6 Gas Compressor?

The Oil-Free SF6 Gas Compressor operates on the principle of oil-free lubrication reciprocating type compressor, ensuring clean compression without any pollution or leakage.

2. What cooling options are available for the compressor?

The compressor can be cooled by either wind or water, allowing for flexibility in different operating environments.

3. What is the power consumption range of the compressor?

The power consumption of the compressor ranges from 1.5 to 45kw, providing options for various applications and energy requirements.

4. What is the maximum outlet pressure of the compressor?

The compressor can achieve an outlet pressure ranging from 2 to 80bar, making it suitable for a wide range of industrial processes.

5. Can the compressor be used for other special gases?

While the compressor is specifically designed for SF6 gas, it can also be used for other special gases that require higher purity and pressure levels.

DISCLAIMER: All content on this page is sourced from the internet and is provided for reference purposes only. Our products are replacement parts, not original spare parts. We do not hold the original trademark of the content. If you require original spare parts, please contact the original factory or supplier.

Performance Characteristics of Gas Air Compressor

High Efficiency

Gas air compressors are known for their high efficiency, allowing them to deliver powerful performance in various applications. Thanks to their design and advanced technology, these compressors can effectively convert gas energy into compressed air, ensuring optimal productivity and performance.

Compact Size

Gas air compressors are designed to be compact, making them suitable for limited space environments. Their small size allows for easy installation and portability, enabling users to conveniently move them from one location to another as needed.

Versatility

Gas air compressors offer a wide range of applications across various industries. Whether it’s in the Oil and Gas Industry, Chemical and Petrochemical Industry, Power Generation, Manufacturing and Industrial Processes, or even Medical and Healthcare fields, gas air compressors prove to be invaluable tools in ensuring smooth operations and reliable performance.

Reliability

Gas air compressors are known for their reliability and durability. With proper maintenance and care, these compressors can provide long-term and consistent performance, minimizing downtime and ensuring a smooth workflow in various industries.

Low Noise and Vibration

Gas air compressors are designed to operate with minimal noise and vibration levels. This makes them suitable for environments where noise pollution and vibrations need to be minimized, such as hospitals, laboratories, and residential areas.

Types and Characteristics of Gas Air Compressor

Reciprocating Gas Air Compressor

Reciprocating gas air compressors operate by using pistons to compress the gas. They are known for their high efficiency and ability to handle high-pressure applications. These compressors are often used in industries that require heavy-duty operations and continuous air supply.

Rotary Screw Gas Air Compressor

Rotary screw gas air compressors use two interlocking helical rotors to compress the gas. They are known for their smooth and continuous operation, making them ideal for applications requiring a steady flow of compressed air. These compressors are often used in manufacturing processes, automotive industry, and construction sites.

Centrifugal Gas Air Compressor

Centrifugal gas air compressors use centrifugal force to compress the gas. They are known for their high flow rates and ability to handle large volumes of compressed air. These compressors are often used in power generation plants, refineries, and chemical industries.

Advantages of Gas Air Compressor Made of Different Materials

Steel Gas Air Compressor

Steel gas air compressors offer durability and strength, making them suitable for heavy-duty applications. They can withstand high pressure and harsh operating conditions, ensuring reliable performance in demanding environments.

Aluminum Gas Air Compressor

Aluminum gas air compressors are lightweight and corrosion-resistant. They are often used in portable applications where mobility is essential. These compressors are also known for their energy efficiency and low maintenance requirements.

Composite Gas Air Compressor

Composite gas air compressors combine the advantages of different materials, such as high strength-to-weight ratio, corrosion resistance, and reduced noise levels. They are often used in industries where weight, noise, and vibration are critical factors.

Future Development Trends and Opportunities of Gas Air Compressor Products

Gas air compressor products are expected to witness significant growth in the coming years. As industries continue to evolve and demand more efficient and sustainable solutions, gas air compressors offer a promising future. The development of advanced technologies, such as IoT integration, energy-saving features, and smart control systems, will drive the market forward. Additionally, the increasing focus on renewable energy sources and environmental regulations will create opportunities for the development of eco-friendly gas air compressors.

How to Choose a Suitable Gas Air Compressor

When choosing a gas air compressor, several factors should be considered:

Clear Requirements

Define your specific requirements, such as desired airflow, pressure, and power source, to ensure the compressor meets your needs effectively.

Material Selection

Consider the material of the compressor based on the application and environment. Factors such as corrosion resistance, weight, and durability should be evaluated.

Design Optimization

Look for compressors with optimized designs that enhance efficiency, reduce noise levels, and improve overall performance.

Suppliers and After-Sales Service

Choose reputable suppliers who offer reliable products and excellent after-sales service, ensuring prompt support and maintenance when needed.

Cost-Effectiveness

Evaluate the long-term cost-effectiveness of the compressor, considering factors such as energy efficiency, maintenance requirements, and lifespan.

Quality Control

Ensure the compressor meets industry standards and certifications, indicating its quality and reliability.

Author: Dream